A jump-start seems simple, but modern cars are packed with sensitive control modules. One bad move can create a voltage spike that damages the engine control unit (ECU), alternator diodes, or body electronics.

Here are the four mistakes that do the most harm and how to avoid them in Tonawanda’s cold starts.

1. Reversing Polarity, Even for a Second

Crossing the cables (+ to – or – to +) is the fastest way to cook electronics. Reversed polarity can send an instant surge through modules, pop fusible links, and pit relay contacts.

How to avoid it:

- Identify the positive post first; it’s red and marked with “+.”

- On vehicles with remote jump posts, use those instead of digging into the battery. Manufacturers place them to protect sensors.

- Connect positive to positive, then negative to a clean engine or chassis ground on the disabled car—not the battery’s negative post if it has an intelligent battery sensor (IBS). Grounding away from the battery reduces spark near vapors and keeps the sensor reading correctly.

If there’s any doubt, stop and recheck. Our technicians see most ECU damage come from a split-second polarity slip.

2. Loose or Dirty Clamps That Arc Under Load

A poor connection creates resistance. When the starter draws current through a sketchy clamp, it arcs. Arcing equals voltage spikes, and spikes travel straight to modules and alternators.

How to avoid it:

- Brush or twist the clamp area to bare, clean metal.

- Seat clamps fully and firmly; don’t grip on paint, plastic covers, or thin brackets.

- Keep the clamp jaws from touching each other or accessories.

- Ask a helper to hold still because wiggling cables while cranking invites arcing.

A quick prep of contact points takes seconds and prevents the crack-snap that cooks electronics.

3. Jumping With the Donor Car Revved (or a Cheap, Unregulated Booster)

Revving the helper car to “give it more juice” used to fly on older iron. Today, it risks voltage spikes as the donor alternator ramps output. Similarly, some bargain booster packs lack good surge protection. Either can overvolt sensitive control units.

How to avoid it:

- Leave the donor car idling at normal speed.

- If using a pack, choose one with overvoltage protection and a reverse-polarity alarm.

- After connections, let the disabled car charge for 2–5 minutes with accessories off before cranking. This pre-charge stabilizes voltage and reduces starter draw shock.

- Never jump from or to a running vehicle with obvious charging faults (battery light on, lights flickering).

4. Disconnecting Cables While the Engine Is Running

Pulling cables the moment the engine fires can create a sudden change in system load. That can spike voltage, stress the alternator, and upset the ECU. It’s the electrical equivalent of slamming a door while someone is carrying dishes.

How to avoid it:

- After the car starts, let it idle a minute with cables attached.

- Turn on a light electrical load (rear defogger or blower on low) to absorb transients.

- Then remove cables in reverse order of installation: ground off first, then positive.

- Don’t allow clamps to touch each other or bodywork during removal.

- Stable voltage for sixty seconds is cheap insurance against module damage.

Cold-Weather Pre-Checks That Prevent Jump-Start Disasters

Tonawanda winters add two risks: frozen batteries and brittle cables. A battery that’s frozen can explode when charged.

Do a quick check:

- If the case is swollen, cracked, or frosted, don’t jump it—tow it.

- Inspect for corroded terminals or loose grounds.

- Turn everything off (lights, HVAC, audio) in the disabled vehicle before connecting.

- Verify the parking brake is set and transmissions are in Park/Neutral.

- These 30-second habits stop most emergencies before they begin.

Safe Jump-Start Sequence (One-Time Quick Reference)

- Park nose-to-nose but not touching; key off both vehicles.

- Connect red (+) to dead positive, then red (+) to donor positive.

- Connect black (–) to donor negative, then black (–) to engine/chassis ground on the dead vehicle.

- Start the donor and let it idle; wait 2–5 minutes.

- Crank the disabled vehicle up to 10 seconds, rest 30 seconds if needed.

- Once running, idle 1 minute, then remove cables in reverse order.

- Drive 20–30 minutes to recharge—or test battery/charging soon.

Use this method and you’ll protect ECUs, alternators, and sensors.

When to Stop and Call for Help

Quit attempting a jump if: cables smoke or spark excessively; the battery case hisses or bulges; the engine cranks slow and all lights dim (possible shorted cell); or there’s a strong sulfur smell. Continued attempts can overheat cables, backfeed modules, and escalate a simple battery issue into a full electrical repair.

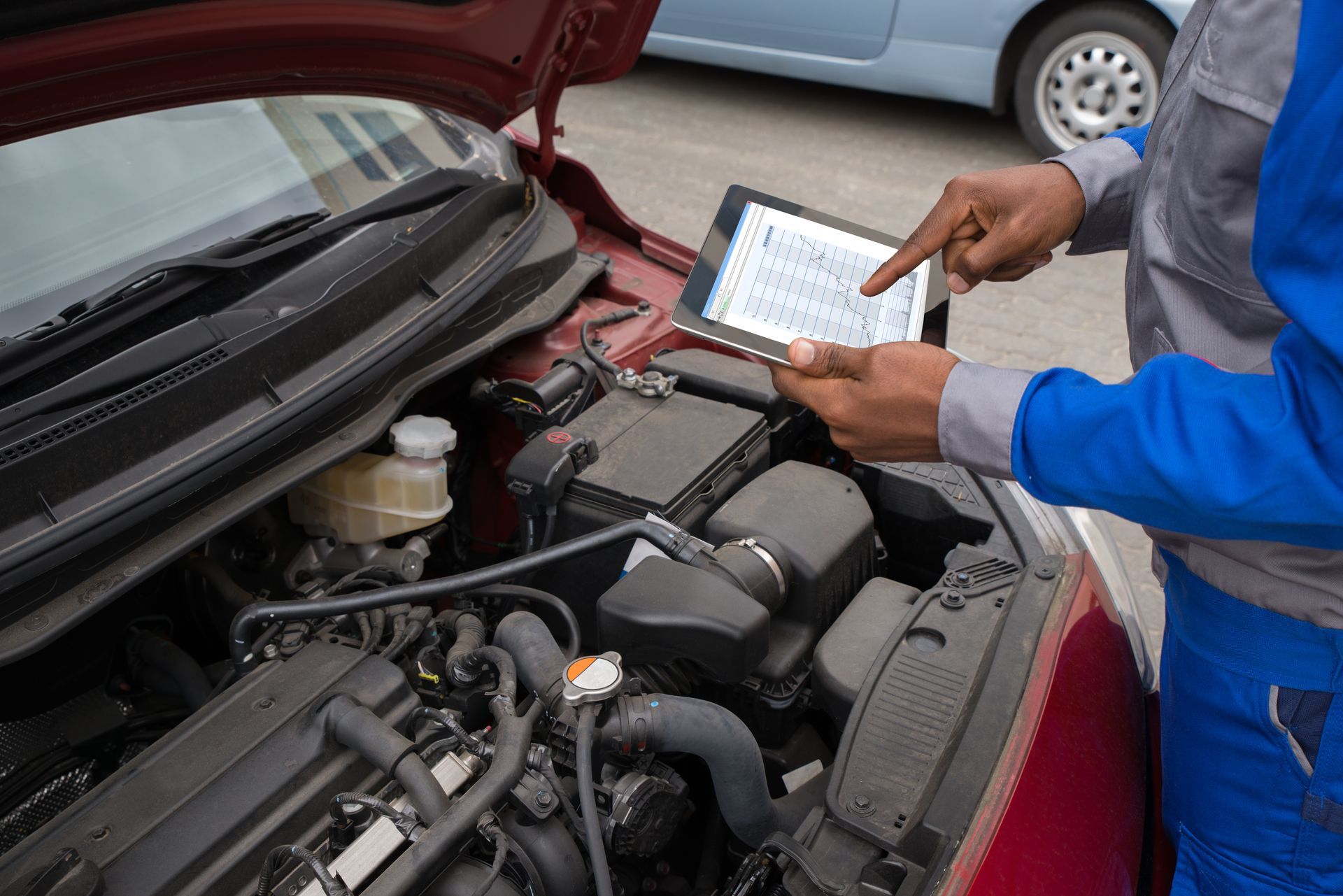

Get Professional Battery and Electrical Service in Tonawanda with WNY One Stop Automotive

If jump-starts keep failing, or you suspect voltage spikes have stressed modules, call our Tonawanda shop. We can load-test the battery, check alternator ripple, inspect grounds, and verify module health so the next cold start is drama-free.

A quick diagnostic now prevents costly electronics later.